YFROBOT

YFROBOT Metal Gearmotor GB37-520 12V with 16 CPR Encoder Hall speed measurement

YFROBOT Metal Gearmotor GB37-520 12V with 16 CPR Encoder Hall speed measurement

Couldn't load pickup availability

Overview

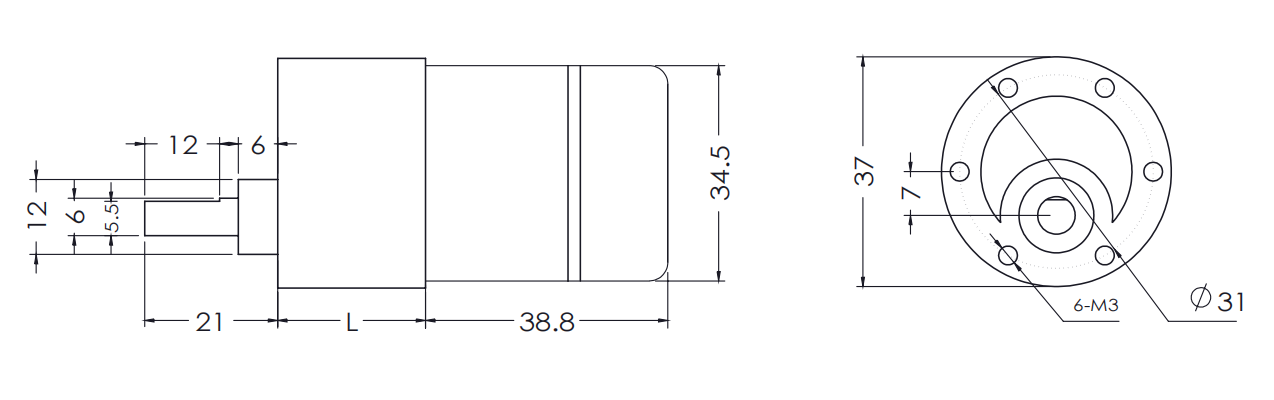

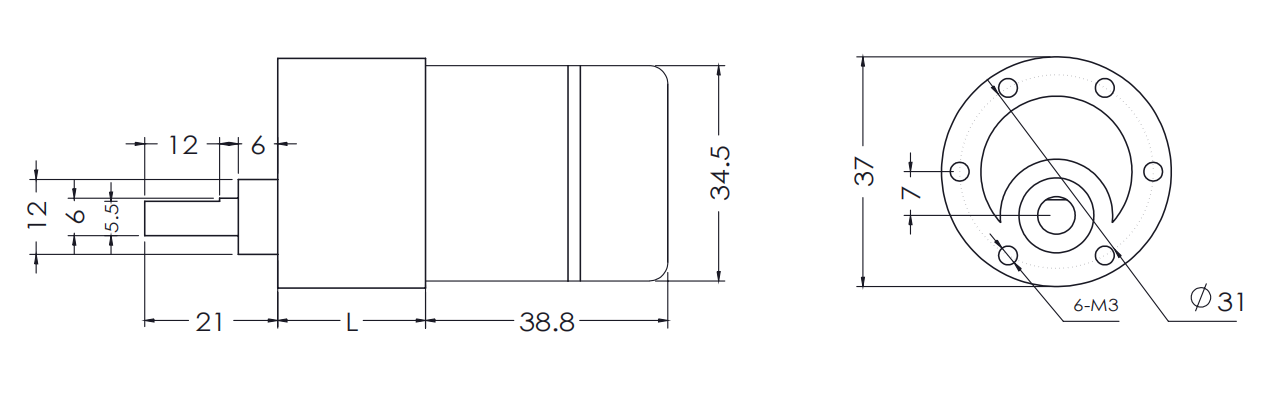

Measuring 37 mm (1.46″) in diameter, these brushed DC gearmotors are the largest and most powerful we carry. all versions are available with integrated 64 CPR quadrature encoders on the motor shafts. The 12 V motors offer approximately the same performance at their respective nominal voltages. Its motor shaft is a 6mm D-shaft.In general, these kinds of motors can run at voltages above and below the nominal voltages; lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.The gearboxes are composed mainly of spur gears, but they feature helical gears for the first stage for reduced noise and improved efficiency:

Using the Encoder

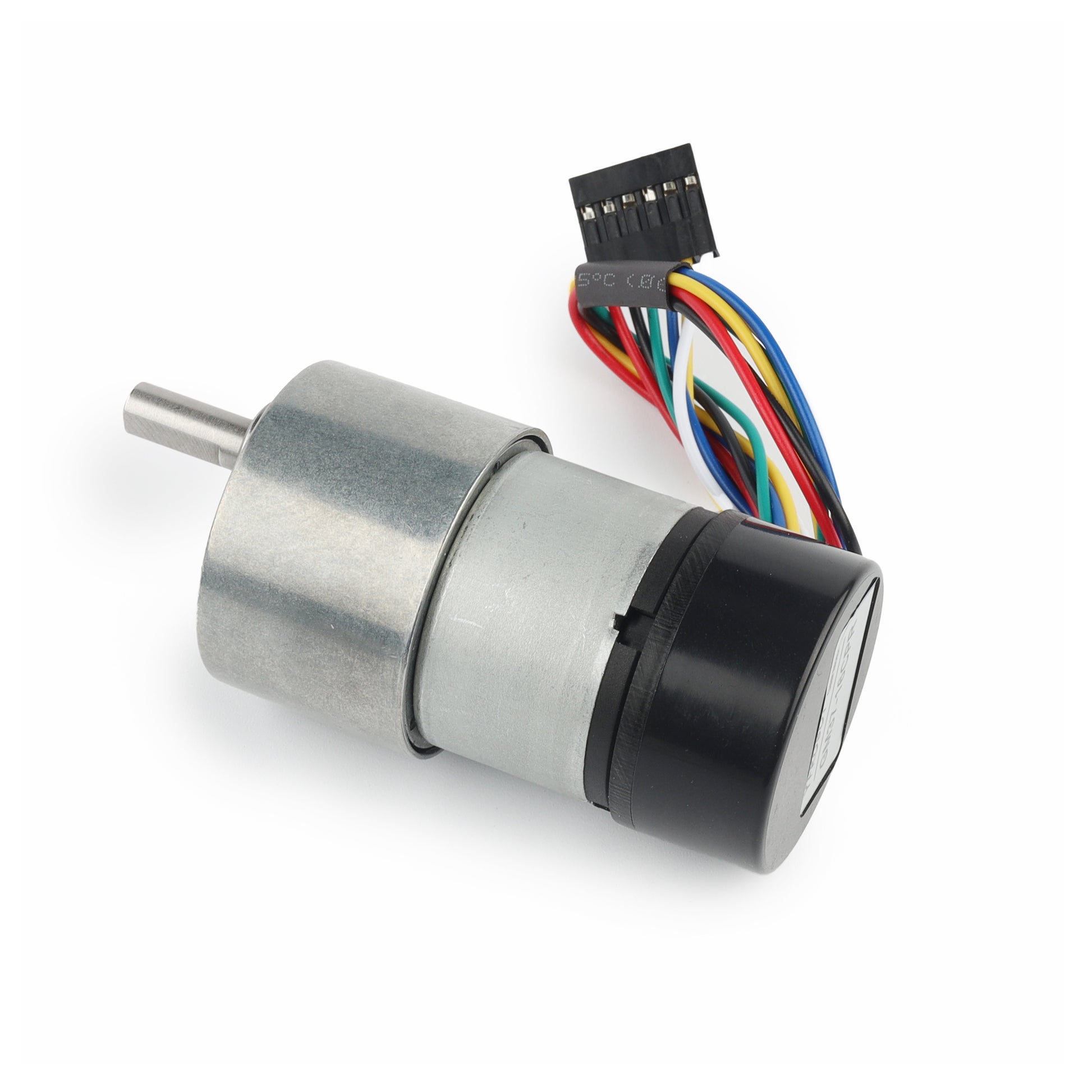

A two-channel Hall effect encoder is used to sense the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 64 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 64. The motor/encoder has six color-coded, 8″ (20 cm) leads terminated by a 1×6 female header with a 0.1″ pitch, as shown in the main product picture. This header works with. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off. The following table describes the wire functions:

| Color | Function |

|---|---|

| Red | motor power (connects to one motor terminal) |

| Black | motor power (connects to the other motor terminal) |

| Green | encoder GND |

| Blue | encoder Vcc (3.5 – 5 V) |

| Yellow | encoder A output |

| White | encoder B output |

The Hall sensor requires an input voltage, Vcc, between 3.5 and 20 V and draws a maximum of 10 mA. The A and B outputs are square waves from 0 V to Vcc approximately 90° out of phase. The frequency of the transitions tells you the speed of the motor, and the order of the transitions tells you the direction. The following oscilloscope capture shows the A and B (yellow and white) encoder outputs using a 12 V motor at 12 V and a Hall sensor Vcc of 5 V:

By counting both the rising and falling edges of both the A and B outputs, it is possible to get 64 counts per revolution of the motor shaft. Using just a single edge of one channel results in 16 counts per revolution of the motor shaft, so the frequency of the A output in the above oscilloscope capture is 16 times the motor rotation frequency.

Precautions

- This product does not have waterproof function, and it is strictly prohibited to use in water or damp environments.

- Short circuit between positive and negative poles is prohibited.

- Obtain information through email.

Motor parameters

|

Reduction Ratio |

Voltage |

Noload Speed (r/min) |

Load Speed (r/min) |

Rated Torque (kg.cm) |

Rated Current (mA) |

Stall Torque (kg.cm) |

Stall Current (mA) |

Power (W) |

|

1:18.8 |

6 |

290 |

220 |

1.0 |

800 |

4.0 |

4400 |

5 |

|

12 |

585 |

440 |

2.0 |

800 |

8.0 |

4400 |

9 |

|

|

1:43.8 |

6 |

120 |

90 |

1.8 |

800 |

9.0 |

4400 |

5 |

|

12 |

250 |

180 |

3.7 |

800 |

18 |

4400 |

9 |

Electrical characteristics

|

Specification |

Symbol |

Test Condition |

Min |

Typical |

Max |

Unit |

|

Input Voltage |

Vcc |

-- |

2.7 |

5 |

5.5 |

V |

|

Output Saturation Voltage |

Vce(sat) |

VCC=14V; IC=20mA |

- |

300 |

700 |

mV |

|

Output Leakage Current |

Icex |

VCC=14V; VCC=14V |

- |

<0.1 |

10 |

A |

|

Input Current |

Ice |

VCC=20V, output open |

- |

5 |

10 |

mA |

|

Output Rise Time |

Tr |

VCC=14V; RH=820Ω;CH=20pF |

- |

0.3 |

1.5 |

S |

|

Output Fall Time |

Tr |

VCC=14V; RL=820Ω;CL=20pF |

- |

0.3 |

1.5 |

S |

|

Operating Temperature Range |

Topr |

|

0-85 |

℃ |

||

Installation method

Introduce your content

Answer your customers' common questions

List a frequently asked question

Then provide an answer that will help your customer make an informed purchase.